Reducing waste and building circular economy

We want to lead the way in eliminating waste.

Our ambition

Belron businesses produce around 160,000 tonnes of waste every year. Our ambition is that none of this waste goes to landfill and that it’s recycled or reused instead.

Vehicle glass is our most significant type of waste and we want to recycle as much as possible of the vehicle glass we handle.

Our ultimate goal is to build a circular economy so that all the glass we fit is made from recycled materials.

Our actions

Glass recycling

Our repair first strategy is at the heart of our business – as a repair prevents a windscreen replacement and so produces a lot less waste and emissions.*

In 2022 we recycled 89% of the vehicle glass we handled, up from 72% in 2021. This gave broken windscreens a new life as bottles and jars, building insulation and carpet backing.

This increase follows our focus on markets where waste and recycling is less well-established e.g. in USA and Canada. Elsewhere, e.g. in Australia and New Zealand, we found new suppliers and alternatives uses of waste vehicle glass.

Our ultimate vision is to fit windscreens made from recycled glass. In an exciting initiative with our partner AGC, we’re trialling the production of windscreens using waste glass gathered from our European Distribution Centre in Belgium

*A windscreen repair results in at least 70% less carbon emissions than a replacement. 2019 product carbon footprint analysis in Germany and France assured by Bureau Veritas

Reducing general waste

In 2022, we generated 54,500 tonnes of general waste. While we sent more than half of this to landfill, this represents a drop of over a third since 2021.

Steps we’re taking to reduce our general waste include:

• transporting and delivering more windscreens without plastic bags;

• reducing the packaging we use for adhesives;

• removing unnecessary waste associated with wipers.

A small change can make a big difference

In Italy, we recycled 1,800 tonnes of our windscreen glass into 2.5cm bottles - including 32,000 special edition Carglass® Italy bottles for our customers. We've featured this in our TV ads and plan to extend this initiative to other countries.

In Germany, we offer customers Greentab, a sustainable product which is mixed with tap water and goes straight into a vehicle's washer fluid tank, creating five litres of windscreen cleaning fluid. Greentab replaces containers of washer fluid, resulting in 99% less plastic waste.

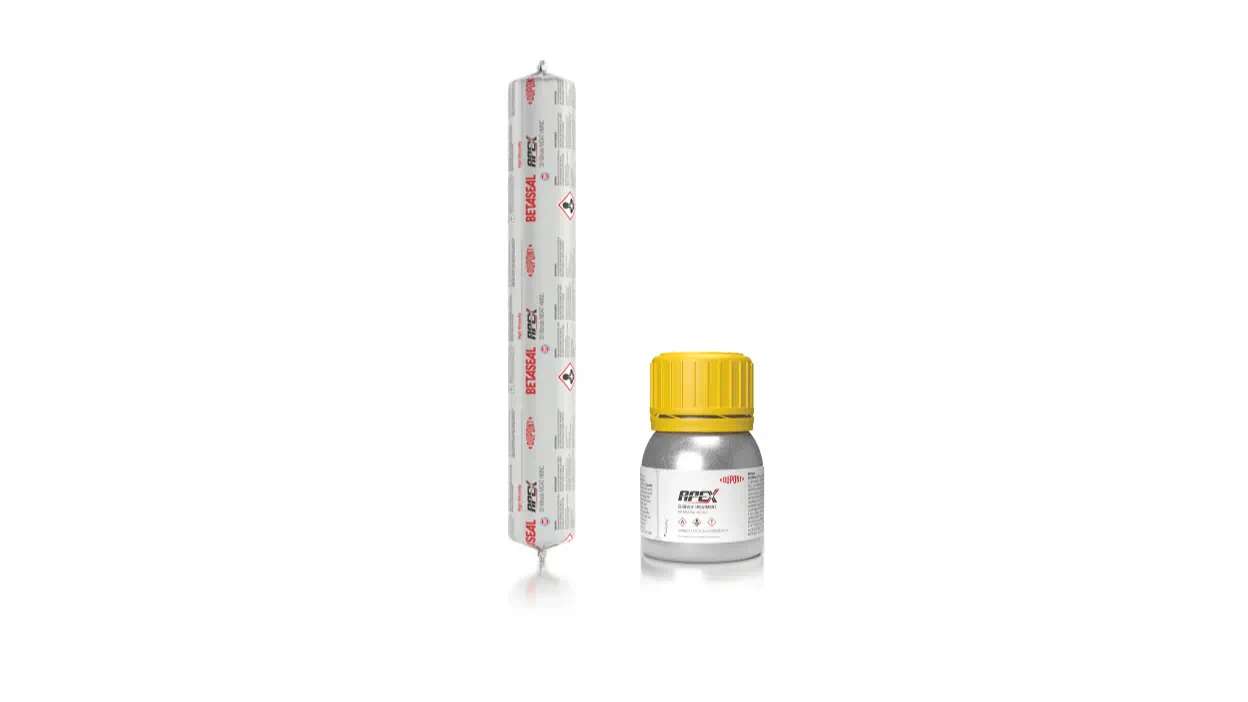

In collaboration with our supplier DuPont™ we developed a new 'primerless-to- glass' adhesive, significantly reducing the need to use primer from a separate aluminium bottle.

Using the BETASEAL™ APEX adhesive will save us around 23 tonnes of metal and two tonnes of plastic caps every year. In New Zealand alone, we're already sending 150kg fewer aluminum bottles to waste every month.

Our Responsible Business Framework summarises our ambitions for doing the right thing

Climate change is a global emergency and we’re taking action to drive down our emissions.